Car Electronics – Innovative, Efficient and Safe

With years of experience as an innovative development service provider to the automobile industry, Solectrix has the complete value creation process down pat. We handle the complete development of new car electronics systems for OEMs and suppliers in all phases of the V model, from the concept and the hardware and software development to testing.

What We Can Do

Our services portfolio ranges from research and predevelopment in the algorithm development field to the development and construction of prototypes and demonstrators and ultimately to the actual series development of digital ECU cores.

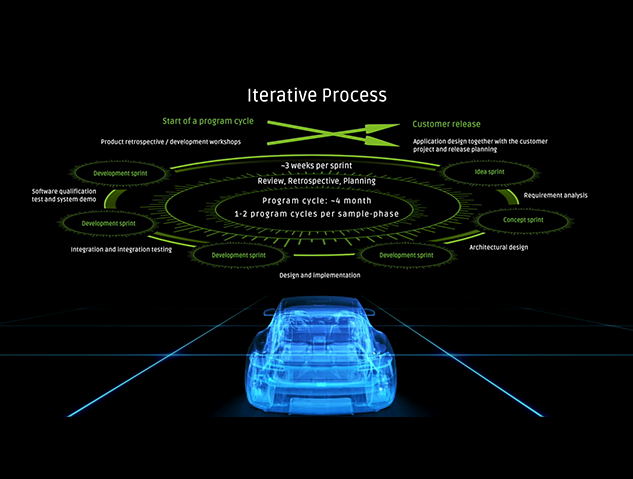

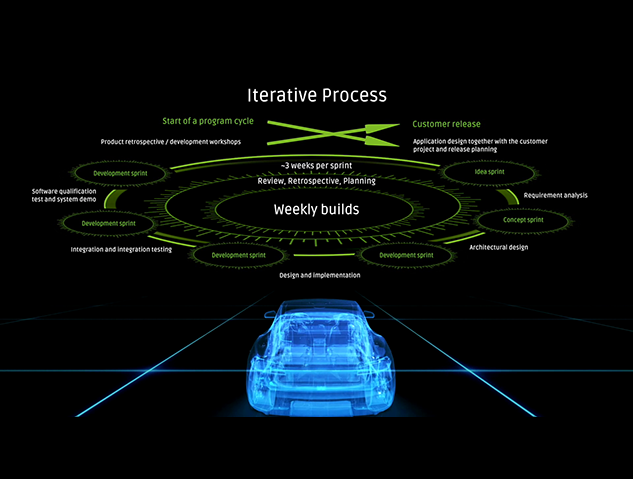

In this we combine agile development methods with the classic V model, but also with aspects of functional safety – as shown in the video.

Series development of digital ECU cores

With a team of qualified engineers from the FPGA, software, hardware and test development fields we cover all areas within this phase. Additionally, we can work on testing concepts at an early stage. In all this, we use contemporary and agile development methods and combine them with functional safety requirements.

What We Are Working On

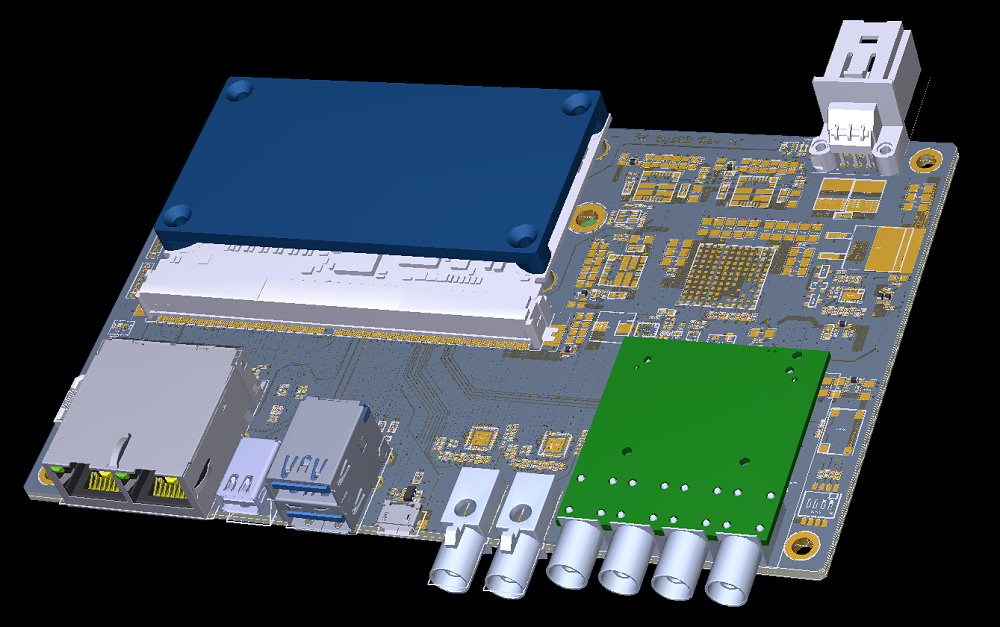

As a development partner for OEMs and suppliers, we are involved in numerous technology projects and customized serial projects. This includes, for example, the pre- and series development in the indirect vision field as in the first series-production digital mirror replacement system for trucks, developed alongside MEKRA Lang. Or the pre- and series development of Ethernet-based camera systems and of FPGA-based or microcontroller-based embedded solutions as well as technology development in the image processing field.

Pre- and series development of indirect vision (mirror replacement system)

Typically, we are involved in the conceptualization of the CMS core features and the setup of functional prototypes. This is followed by the series development of the CMS image processing with due regard to functional safety. For one, it is important to bear in mind that the system is a safety-relevant part of the vehicle for ensuring indirect vision and thus ISO 26262, among others, needs to be adhered to. Second, such a CMS must meet high specific image quality criteria for latency-optimized presentation on the monitor, but also as a basis for subsequent topics like object detection or other ADAS functionalities.

Pre- and series development of Ethernet-based camera systems

Here we develop either Ethernet-based cameras that have to be integrated into the smallest spaces, or we realize the additional output of compressed image data streams for downstream functionalities within a central control unit. In both cases, established standards in the automotive Ethernet field can be supported, for example SOME/IP. Here we can support our customers in all areas, from optimized smart cameras to flexible system architectures.

Technology development image processing

In the research and predevelopment field, we deal with conceptualization and prototypical implementation of the following topics:

- Camera demonstrators with new image sensors

- 3D environment monitoring using stereo vision

- 2D image analysis with classic methods for object and line detection

- Machine learning and integration of neural networks

Pre- and series development of FPGA-based embedded solutions

We handle complete FPGA development, from FPGA-centric systems to the simple implementation of hardware accelerators within the FPGA fabric. Series development projects are based not only on Automotive SPICE-compliant VHDL development and thus on the same lifecycle as classic software, but also on safeguards regarding functional safety according to ISO 26262.

Pre- and series development of microcontroller-based embedded solutions

We handle the complete software lifecycle from conception, SW requirements, architecture and design to testing, taking into account market-specific aspects like Automotive SPICE, functional safety (ISO 26262), security, Ethernet, CAN, diagnosis, update, AUTOSAR, etc.

How We Work

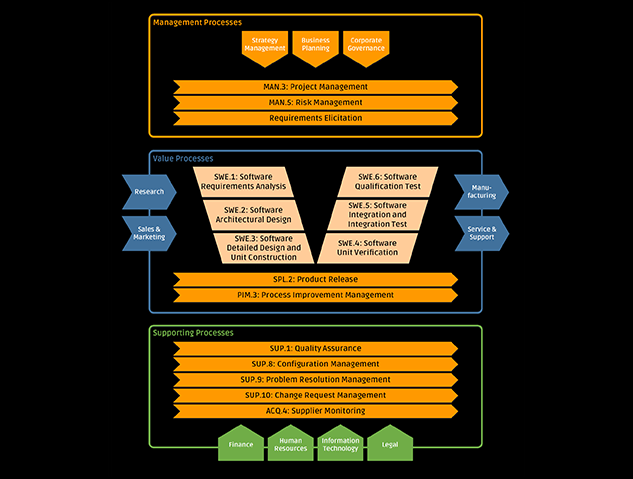

Increasingly complex electronic components and higher safety standards call for most reliable and simultaneously efficient software development. Thus, we combine the classic approach according to the V model with agile development methods, placing great value on open and standardized architectures and an understanding of quality that covers the entire development cycle.

Thus we work based on a custom-tailored, generic software development process (Automotive SPICE), contemporary workflows and the “zero defects” strategy. We develop safety-relevant systems according to the ASIL classification (Automotive Safety Integrity Level) or respective provisions. We achieve efficient working while adhering to the highest quality standards by using the DevOps approach and our ISO 9001-certified quality management system.

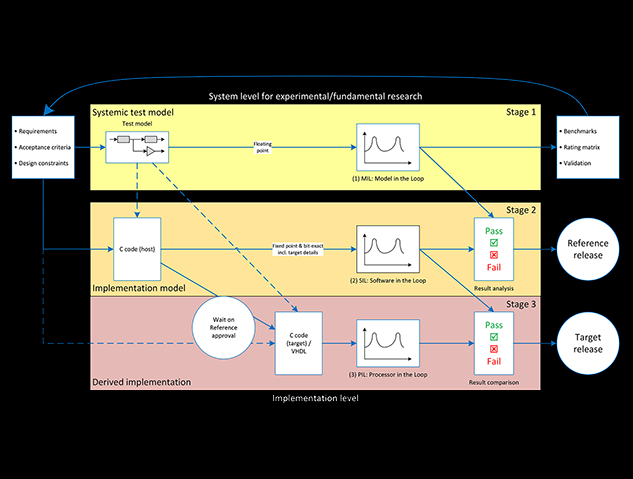

Software development process

We use a generic software development process (Automotive SPICE) that is applied in a custom-tailored manner depending on the project. We place particular value on the use of up-to-date workflows and the adherence to the “zero defects” strategy through quality assurance measures. We apply this to FPGA development in the same way and with similar tools as in classic software development, i.e., independent from the realization, topics like guidelines, coding styles, static code analysis, unit tests and so on are clearly defined.

Quality management according to ISO 9001

What We Offer

As a competent development partner, we deliver innovative individual solutions and specialist know-how in the field of electronics development. In prototyping and series development, our competence covers the following areas:

- Support in system engineering and testing

- Conceptualization of the system architecture

- Algorithm development, evaluation and visualization in reference models

- Conceptualization of camera systems

- Complete handling of the component development for digital cores

For prototyping as well as for series development, we offer you software, hardware and mechanics from a single source, perfectly matched and meeting your demands in an optimal way. Our solutions include highly integrated electronics and high-speed processor assemblies with complex user interfaces and programmable logic that we embed into your system perfectly.

Conceptualization and setup of the hardware

- State-of-the-art processors and SoCs

- Integration of FPGAs

- Analog design

FPGA/SoC development

- Digital signal processing (e.g., for image processing (ISP) or SensorFusion)

- Safe control of real-time critical applications

- Safety-relevant functions according to functional safety norms

- Integration of various pattern recognition methods

- Safety architectures based on isolation logic

- Integration of hardware accelerators within the FPGA fabric

- The technology portfolio of Solectrix GmbH includes, among others, AMD, Intel and Lattice FPGAs and AMD MPSoCs.

Software development

- Software development for all common microcontrollers

- Experience with classic operating systems, from AUTOSAR to Linux

- Low-level drivers and hardware abstraction layer

- Software update management & diagnosis

- Integration of „Security & Functional Safety“

- Customer-specific application development incl. GUIs

Certifications and norms

We work according to norms and guidelines like:

- Automotive SPICE

- ISO 9001: „Quality management systems — Requirements“

- ISO 16505: „Road vehicles — Ergonomic and performance aspects of Camera Monitor Systems — Requirements and test procedures“

- ISO 26262: „Road vehicles — Functional safety“

- ECE-R 46: „Devices for indirect vision“